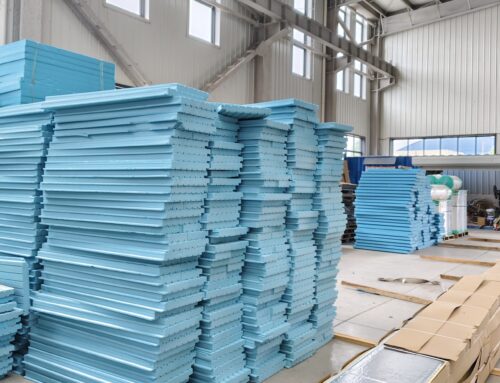

· Polyurethane sandwich panels are a type of composite material that consists of two thin layers of metal or plastic film sandwiched around a core made of polyurethane. Polyurethane sandwich panels have a variety of applications, including insulation, sound insulation, and construction.

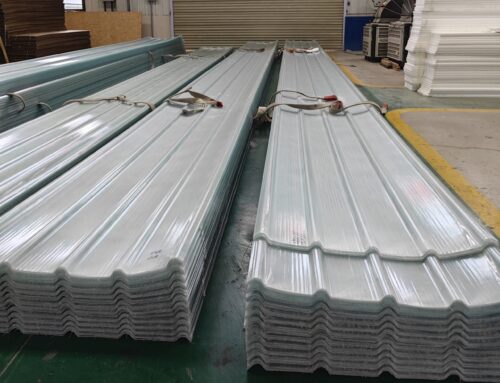

The benefits of polyurethane sandwich panels include their high insulation performance, which helps to reduce energy consumption and save on energy costs. They also have good sound insulation properties, which make them ideal for use in noisy environments where noise reduction is necessary. Additionally, polyurethane sandwich panels are lightweight and easy to install, making them a practical choice for construction projects.

Polyurethane sandwich panels can be produced in a variety of shapes and sizes to meet the specific needs of different applications. They also have good mechanical properties, including high strength and stiffness, which make them suitable for use in high-stress environments. Furthermore, polyurethane sandwich panels are resistant to moisture, insects, and UV rays, ensuring their longevity in outdoor applications.

The production process of polyurethane sandwich panels typically involves the injection of polyurethane foam into a thin metal or plastic film between two layers of polyurethane foam. The resulting panel has a core made of polyurethane foam, which is sandwiched between two layers of metal or plastic film.

In summary, polyurethane sandwich panels are a versatile material that has a variety of applications in insulation, sound insulation, and construction. Their high insulation performance, good sound insulation properties, and ease of installation make them a practical choice for many projects.