Product Paramenters:

EPS and XPS sandwich panels differ significantly in terms of thermal insulation performance, strength, weather resistance, bonding strength, and surface flatness. Here are the specific comparisons:

Thermal insulation performance: EPS and XPS sandwich panels have gradually increasing insulation performance with increasing thickness, but XPS sandwich panels are typically thinner than EPS panels. Therefore, XPS sandwich panels are more expensive than EPS panels when achieving the same insulation performance.

Strength: The strength of XPS sandwich panels is typically above 150KPa-700KPa, while the strength of EPS panels is typically below 100KPa. Therefore, for some high-rise buildings, both types of panels may require reinforcement or additional fasteners for reliable installation.

Weather resistance: Due to the higher water absorption of EPS panels compared to XPS, the latter typically has better weather resistance. However, the ductility of EPS panels is superior to that of XPS panels, which can compensate for some of its limitations.

Bonding strength: The stronger bond of XPS sandwich panels compared to EPS panels is more reliable.

Surface flatness: The surface flatness of XPS sandwich panels depends on the raw materials and production equipment used. Native material XPS sandwich panels have superior surface flatness compared to secondary recycled material XPS sandwich panels.

| Name | XPS Sandwich Panel |

| Raw materials | EXS/XPS board/cement ect |

| Project Solution Capability | total solution for projects, Others |

| Design Style | Modern |

| After-sale Service | Online technical support, Onsite Installation, Free spare parts.Other |

| Feature | Soundproof, Environmental, Light Weight |

| Type | Insulation Material |

| Video outgoing-inspection | Provided |

| Key Selling Points | High cost performance |

| Length | Customized |

| Product width | 38.3cm |

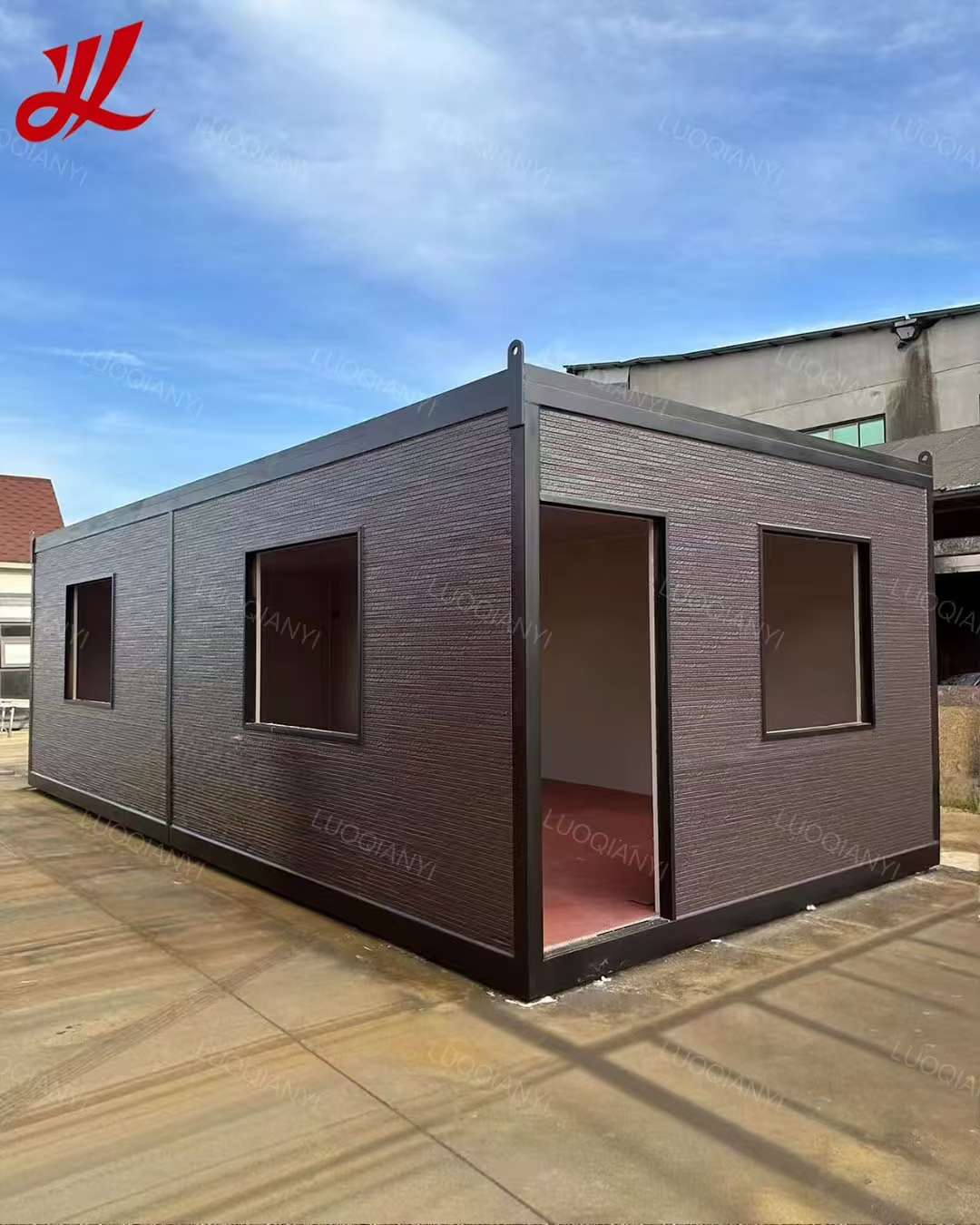

| Application | Roof, Hotel, Villa, Apartment, Office Building, Hospital, School.Mall, supermarket, Workshop, Farmhouse, Hall, Building exteriorwall and interior partition |

| Product length | 0.1 ≤ L ≤ 11.8 meter |

| Lifespan | More than 20 years |

| Power | 50-80KW |

Color and Pattern Introduction:

LQYPANEL sandwich panels have over 1000 patterns. The dreamy decorative effect highlights the grade of the building. The simple and flexible disassembly and assembly of these metal side lines make it easy to replace wall designs. Metal wall panels are not only suitable for thermal insulation decoration of new brick concrete structures, frame structures, steel structures, and lightweight exterior walls of buildings, but also for energy-saving renovation of existing buildings and internal and external decoration.

Customer instance:

FAQ

1. Q:Are you a manufacturer or a trading company?

A: We are a sandwich panel manufacturer with 15 years of professional experience in this field.

2. Q: What is your minimum order quantity?

A:100 square meters.

3. Q: delivery date?

A: According to your quantity. Taking 40HQ as an example, the goods will be delivered within 15 days after the advance payment.

4. Q: Are samples are available, are they free?

A:Yes, the samples are free, but you need to pay for shipping. If you order products from us, the shipping cost will of course berefunded to you.

5. Q: What if we still need accessories?

A: U-shaped groove base, inner and outer corners, aluminum profiles and other accessories can be provided.

6. Q: What are your payment terms?

A:T/T proforma invoice has 30% deposit, and the balance before shipment is 70%.

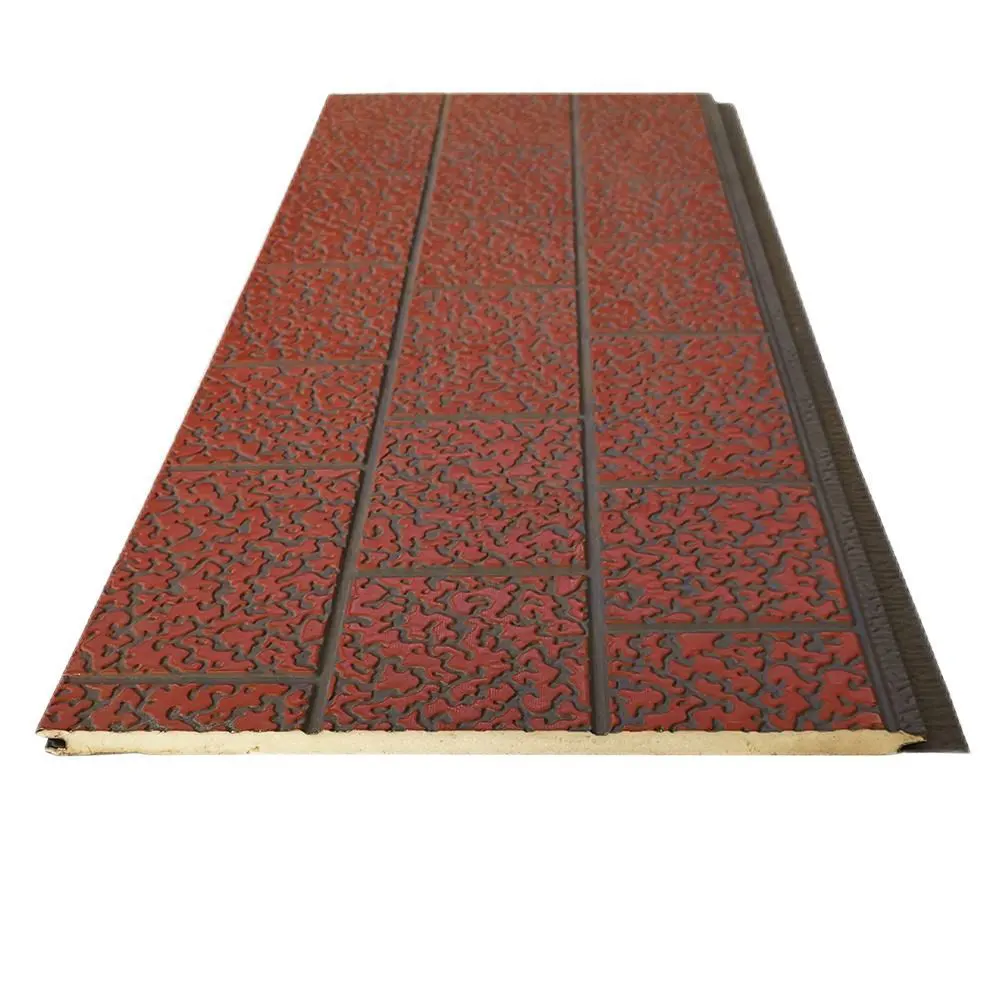

7. Q:What are the main pattern options?

A: Brick pattern,elastic paint pattern,granite pattern,stone pattern,mosaic pattern,tile pattern,long stone pattern,marble pattern,flat pattern,wood pattern and etc.

The reasons for choosing polyurethane sandwich panels are as follows:

Excellent insulation performance: With a low thermal conductivity, polyurethane sandwich panels can effectively inhibit temperature fluctuations and maintain stable interior temperatures.

High safety: Polyurethane sandwich panels are non-flammable, do not produce open flames, and will not release harmful gases when exposed to fire sources. Good impact resistance and durability.

Good cost-effectiveness: Although the unit cost of polyurethane is higher than some traditional insulation materials, its excellent insulation performance can reduce heating and cooling costs, offsetting the additional material cost.

Fire resistance: Polyurethane is flame-retardant and self-extinguishing. It has a softening point above 250 degrees Celsius and will only decompose at high temperatures. Additionally, it forms carbon on its surface when burned, helping to isolate the fire and prevent its spread.

Moisture resistance: The closed-cell structure of polyurethane has a moisture barrier effect, with a water absorption rate lower than 1%. It is a moisture-resistant material that will not be damaged by moisture or water penetration.

Therefore, polyurethane sandwich panels are an ideal choice for applications such as refrigerated vehicles, building insulation, and others requiring high insulation performance, safety, and durability.

Polyurethane(PU) interior and exterior wall decorative insulation sandwich panels

Category:Polyurethane sandwich panel

Category:Polyurethane sandwich panel

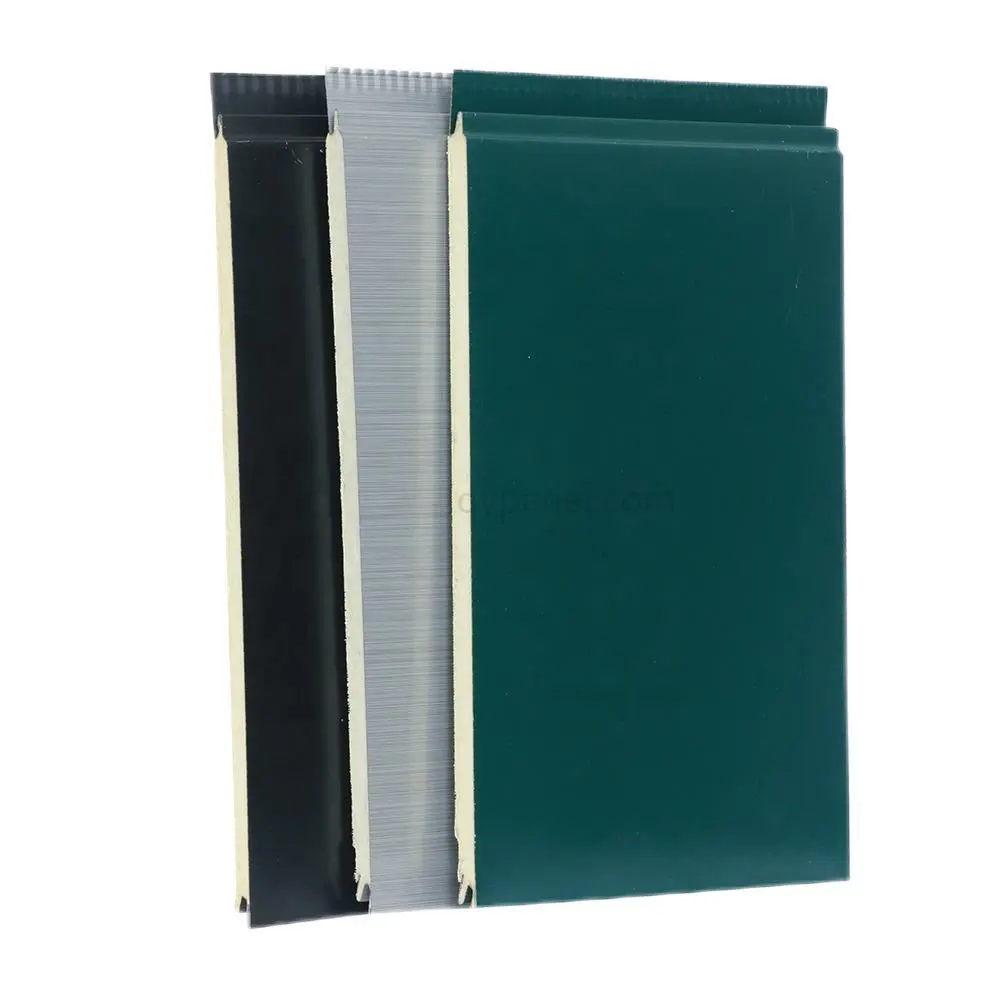

Panel practical width: 38.3cm

Panel length: 2000 ≤ L ≤ 15000

Panel thickness: 14, 16, 20, 25, 30, 50, 70mm

Top material: aluminum zinc plated steel plate 0.25mm

Core materials: PU, EPS, XPS

Bottom material: aluminum foil paper, aluminum zinc coated steel plate 0.25mm

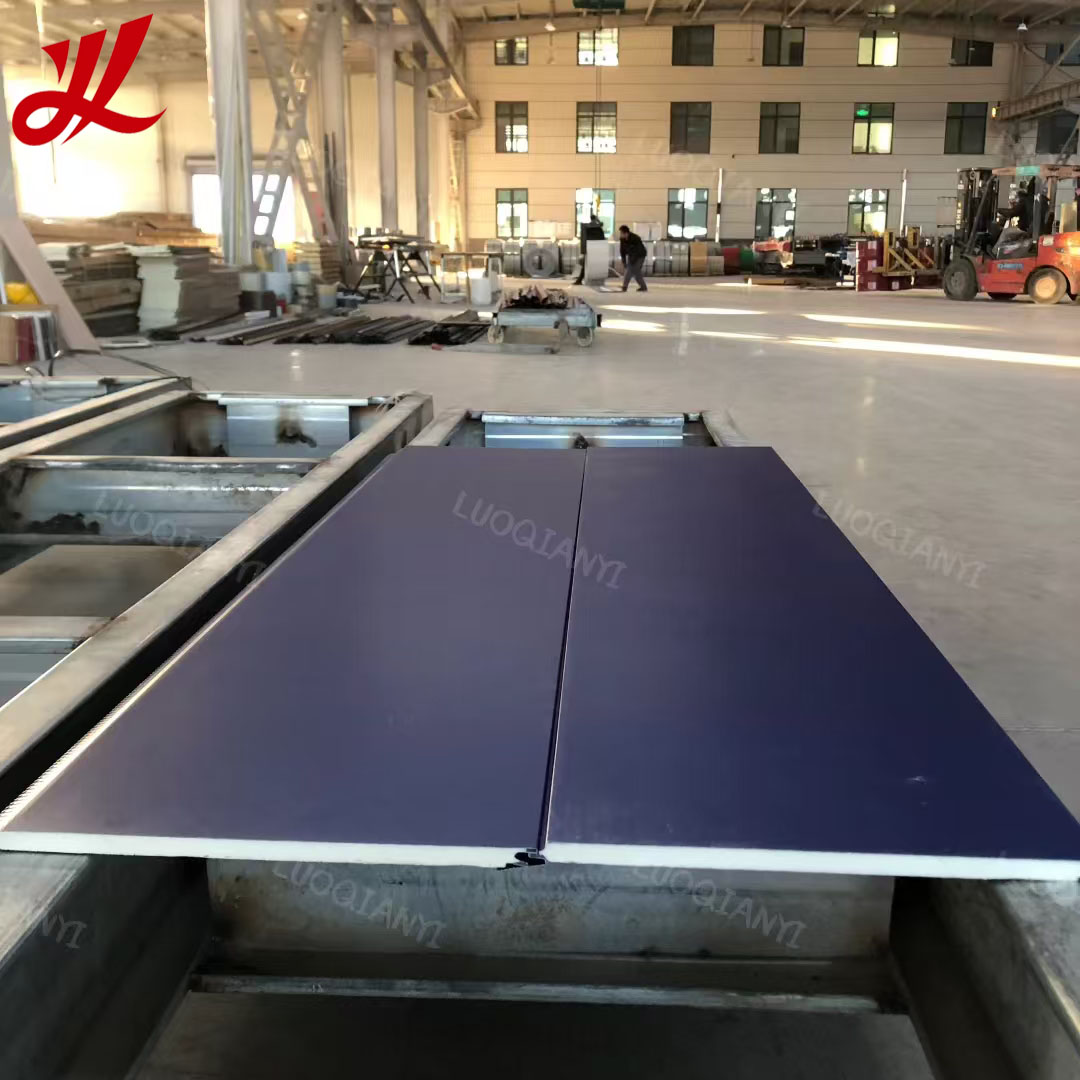

Product Paramenters:

| Name | Polyurethane Sandwich Panel |

| Function | Waterproof, fast installation, eco-friendly, thermal insulation, sound insulation, durable, 3D pattern |

| Standard Size | Length: 3800mm/5800mm*Width: 383mm* Thickness: 14-25mm |

| Usage | Interior and exterior walls and ceiling decoration insulation |

| Surface Material | Galvalume steel plate |

| Core Material | Polyurethane,42kg/m³ |

| Bottom Material | Aluminum foil insulation layer |

| Metal thickness | 0.23-0.27mm |

| Product weight | 3.7kg/㎡ |

| Package | (0-6000mm)*44mm*165mm(10 pieces/carton) |

| Container Capacity | 20GP:1200㎡=12912 sq.ft(panel length:5800mm) |

| 40GP:2800㎡=30128 sq.ft(panel length:3800mm) | |

| 40HQ:3000㎡=32280 sq.ft(panel length:3800mm) | |

| R-VALUE | 0.55 mk/w |

| Heat conductivity | 0.024 w/m*k(in theory) |

| Certificate | ISO9001,CE |

| Fire resistance level | B1/B2 |

| Tensile bond strength | 0.17MPA |

| Wind load value | 9KPA |

| After-sale Service | Online traing,online technical support |

| Port | QINGDAONingboTianjin |

| Payment | L/CWestern UnionD/PD/AT/TMoneyGram |

| Brand | lqypanel |

Color and Pattern Introduction:

LQYPANEL sandwich panels have over 1000 patterns. The dreamy decorative effect highlights the grade of the building. The simple and flexible disassembly and assembly of these metal side lines make it easy to replace wall designs. Metal wall panels are not only suitable for thermal insulation decoration of new brick concrete structures, frame structures, steel structures, and lightweight exterior walls of buildings, but also for energy-saving renovation of existing buildings and internal and external decoration.

Customer instance:

FAQ

1. Q:Are you a manufacturer or a trading company?

A: We are a sandwich panel manufacturer with 15 years of professional experience in this field.

2. Q: What is your minimum order quantity?

A:100 square meters.

3. Q: delivery date?

A: According to your quantity. Taking 40HQ as an example, the goods will be delivered within 15 days after the advance payment.

4. Q: Are samples are available, are they free?

A:Yes, the samples are free, but you need to pay for shipping. If you order products from us, the shipping cost will of course berefunded to you.

5. Q: What if we still need accessories?

A: U-shaped groove base, inner and outer corners, aluminum profiles and other accessories can be provided.

6. Q: What are your payment terms?

A:T/T proforma invoice has 30% deposit, and the balance before shipment is 70%.

7. Q:What are the main pattern options?

A: Brick pattern,elastic paint pattern,granite pattern,stone pattern,mosaic pattern,tile pattern,long stone pattern,marble pattern,flat pattern,wood pattern and etc.

The reasons for choosing polyurethane sandwich panels are as follows:

Excellent insulation performance: With a low thermal conductivity, polyurethane sandwich panels can effectively inhibit temperature fluctuations and maintain stable interior temperatures.

High safety: Polyurethane sandwich panels are non-flammable, do not produce open flames, and will not release harmful gases when exposed to fire sources. Good impact resistance and durability.

Good cost-effectiveness: Although the unit cost of polyurethane is higher than some traditional insulation materials, its excellent insulation performance can reduce heating and cooling costs, offsetting the additional material cost.

Fire resistance: Polyurethane is flame-retardant and self-extinguishing. It has a softening point above 250 degrees Celsius and will only decompose at high temperatures. Additionally, it forms carbon on its surface when burned, helping to isolate the fire and prevent its spread.

Moisture resistance: The closed-cell structure of polyurethane has a moisture barrier effect, with a water absorption rate lower than 1%. It is a moisture-resistant material that will not be damaged by moisture or water penetration.

Therefore, polyurethane sandwich panels are an ideal choice for applications such as refrigerated vehicles, building insulation, and others requiring high insulation performance, safety, and durability.