XPS interior and exterior wall decorative insulation sandwich panels

Category:XPS sandwich panel

Category:XPS sandwich panel

EPS and XPS sandwich panels differ significantly in terms of thermal insulation performance, strength, weather resistance, bonding strength, and surface flatness. Here are the specific comparisons:

Thermal insulation performance: EPS and XPS sandwich panels have gradually increasing insulation performance with increasing thickness, but XPS sandwich panels are typically thinner than EPS panels. Therefore, XPS sandwich panels are more expensive than EPS panels when achieving the same insulation performance.

Strength: The strength of XPS sandwich panels is typically above 150KPa-700KPa, while the strength of EPS panels is typically below 100KPa. Therefore, for some high-rise buildings, both types of panels may require reinforcement or additional fasteners for reliable installation.

Weather resistance: Due to the higher water absorption of EPS panels compared to XPS, the latter typically has better weather resistance. However, the ductility of EPS panels is superior to that of XPS panels, which can compensate for some of its limitations.

Bonding strength: The stronger bond of XPS sandwich panels compared to EPS panels is more reliable.

Surface flatness: The surface flatness of XPS sandwich panels depends on the raw materials and production equipment used. Native material XPS sandwich panels have superior surface flatness compared to secondary recycled material XPS sandwich panels.

The reasons for choosing polyurethane sandwich panels are as follows:

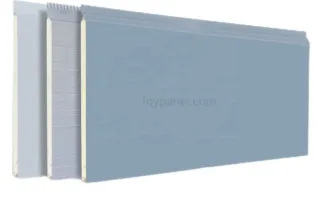

XPS sandwich panel is a high-performance insulation material consisting of two steel plates with XPS foam sandwiched in between. This sandwich panel boasts excellent insulation and soundproofing performance, making it widely used in construction and industrial applications.

XPS sandwich panel is a hard and high-thermal-impedance insulation material with excellent thermal insulation and compressive strength. Its smooth surface can be used as interior and exterior wall panels, roof panels, and floor panels. Moreover, this sandwich panel features good waterproof performance and corrosion resistance, making it suitable for use in different environments.

XPS sandwich panel is manufactured using a continuous extrusion molding production line, resulting in high production efficiency, stable quality, and consistent performance. The core material uses high-expansion polyethylene beads for foaming, which has the advantages of high closed-cell content, low thermal conductivity, and good durability.

XPS sandwich panel has excellent insulation performance, effectively reducing energy consumption and greenhouse gas emissions. It also has superb soundproofing performance, able to reduce noise pollution and interference. In addition, this sandwich panel has good fire-resistant properties and corrosion resistance, making it suitable for use in different environments.

In summary, XPS sandwich panel is an efficient, environmentally friendly, safe, and durable building material widely used in construction and industrial applications. With a wide range of applications, it can meet different needs and requirements.

Product Paramenters:

Thermal conductivity: 0.57-0.114kal/m2h ℃.

Temperature limit: -50 ℃~+120 ℃.

Oxygen index (01): 34.0 (Provincial Fire Products Quality Inspection Station).

Sound insulation performance: 19dB (75mm).

Oxidation index: OI ≥ 34.0.

Combustion performance: B1 grade (flame retardant).

Material application: The thickness of the steel plate is 0.25-0.8mm above/below, and the color steel plate/electric and hot-dip galvanized plate/stainless steel plate is used. The core material, polypropylene ethylene (EPS), has a capacity of 12-16kg/m3.